Description

Description

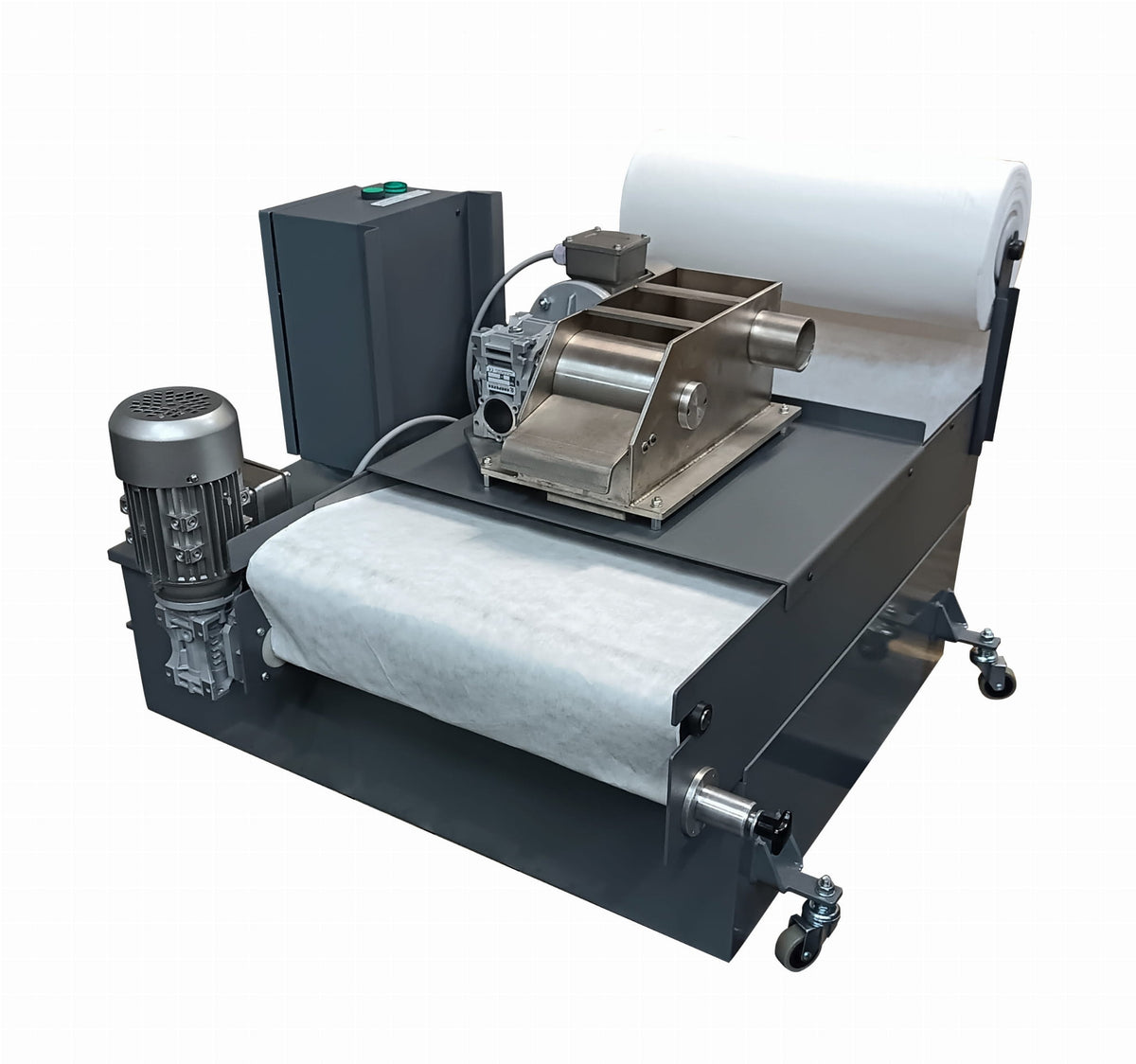

MS60+PS60 Coolant Separator – Double Filtration for Maximum Purity

The MS60+PS60 is an advanced coolant filtration system that combines the benefits of a magnetic and non-woven separator. This ensures effective removal of both magnetic contaminants (e.g., metal chips) and non-magnetic contaminants (e.g., grinding wheel dust or carbide particles).

This kit is ideal for machines requiring exceptionally clean coolant, which translates into longer tool life and improved machining quality.

Principle of operation

Initial stage – MS60 magnetic separator

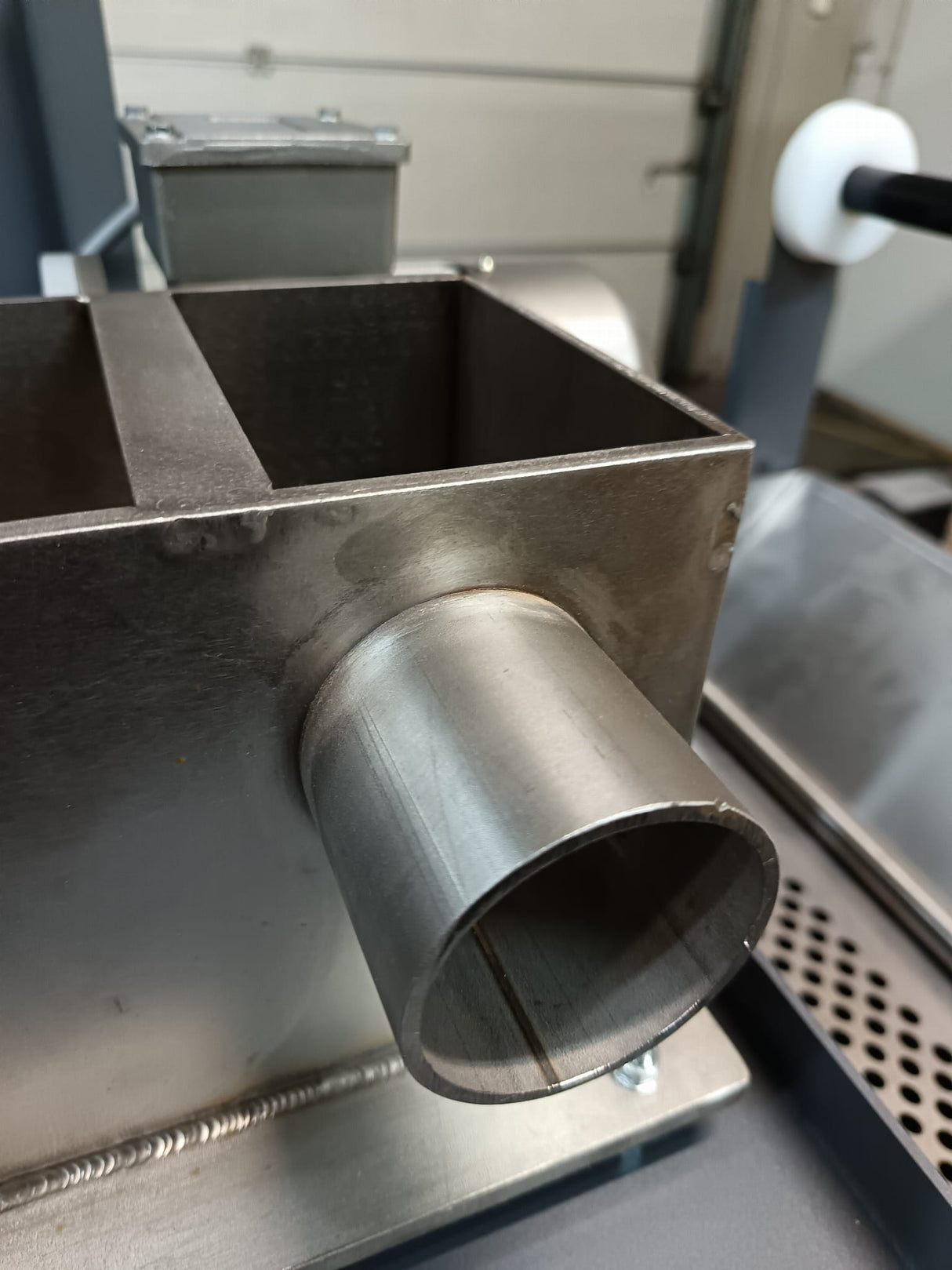

Coolant contaminated with magnetic particles is placed on a rotating magnetic drum made of stainless steel with neodymium magnets. The drum attracts and retains the metal particles, while the cleaned coolant flows through. Contaminants are removed from the drum surface using a scraper.Main stage – PS60 non-woven separator

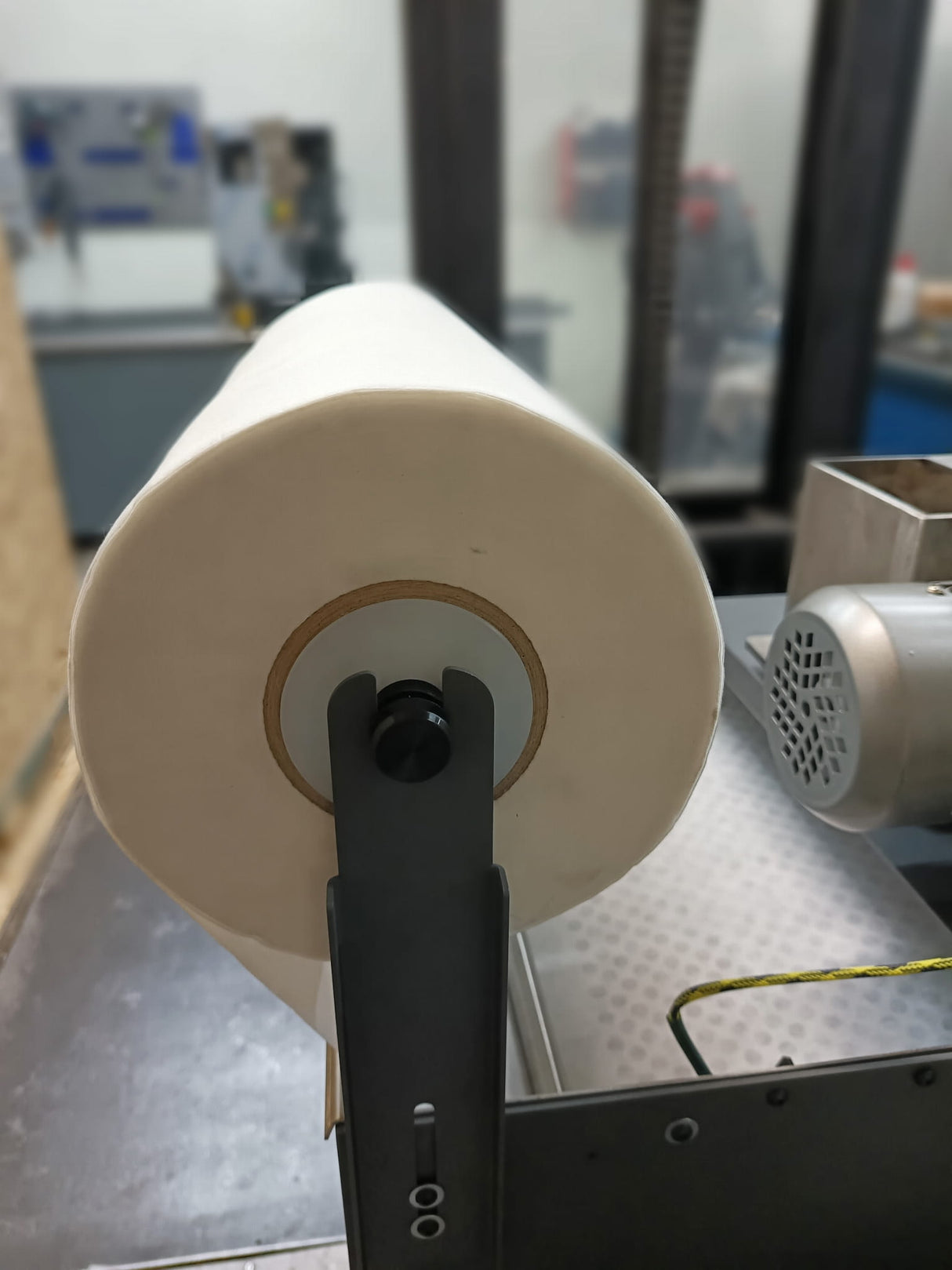

Coolant then flows through a filter fabric of appropriate weight, which traps fine non-magnetic particles. When the contamination level reaches a certain level, a float sensor activates the fabric advance, winding the used material onto the roller and feeding in a new section of fabric. This process is automatic.

Application

The MS60+PS60 set is suitable for:

-

Lathes

Milling machines

Grinders

Machining centers

Machines requiring high coolant purity

Set performance

Coolant flow : 60 L/min

The set includes:

-

MS60 magnetic separator with rotating magnetic drum

PS60 nonwoven separator with automatic nonwoven feed

-

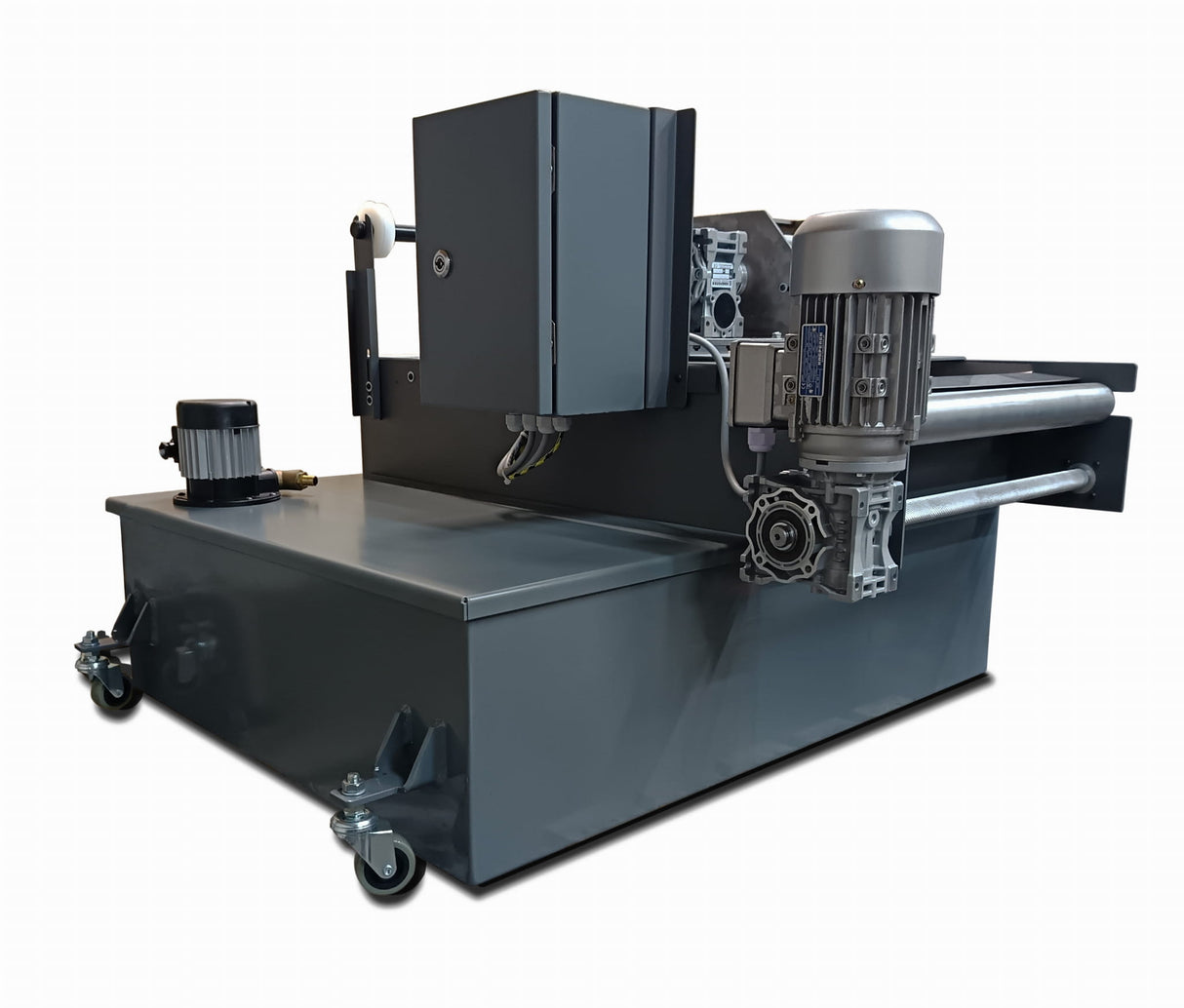

Mobile tank on wheels with a capacity of 150 L , equipped with:

1/2 inch drain valve

Bulkheads directing coolant flow

Coolant pump with a power of 0.09 kW

Electrical box with switch and protection

Coolant level sensor controlling the nonwoven fabric feed

A set of starter fabric on a roller

Power wiring - ready to connect

Technical specifications

MS60 separator material : Stainless steel (base 10 mm, walls 5 mm)

Magnetic drum : Stainless steel tube with neodymium magnets

MS60 separator drive : 0.09 kW motor, 900 rpm + i80 gearbox

PS60 separator drive : 0.09 kW motor, 900 rpm + i80 gearbox

-

Inlet port diameter : 60 mm

Filter fabric : Available weights from 18 to 110 g/m²

Set dimensions : Length 120 cm, width 100 cm, height 70 cm

Coolant inlet height : 500 mm

Set weight : 200 kg

-

Housing color : RAL7012

Why choose MS60+PS60?

Comprehensive filtration : Removes both magnetic and non-magnetic contaminants

Automatic operation : Minimizes the need for operator intervention

High performance : Coolant flow up to 60 L/min

-

Solid construction : Made of high-quality steel, tightly welded, powder coated,

Mobility : The tank is on wheels for easy movement

Polish production : Guaranteed quality and availability of spare parts

- Technical documentation , diagrams, CE, user manual in Polish,

100% Polish product – designed and manufactured by GRAFS Technology.

MS60+PS60 FILTER in detail

Compact magnetic-fiber coolant filter for milling machines, lathes, and grinders